◐ Cov qauv khoom siv thiab cov qauv ua haujlwm

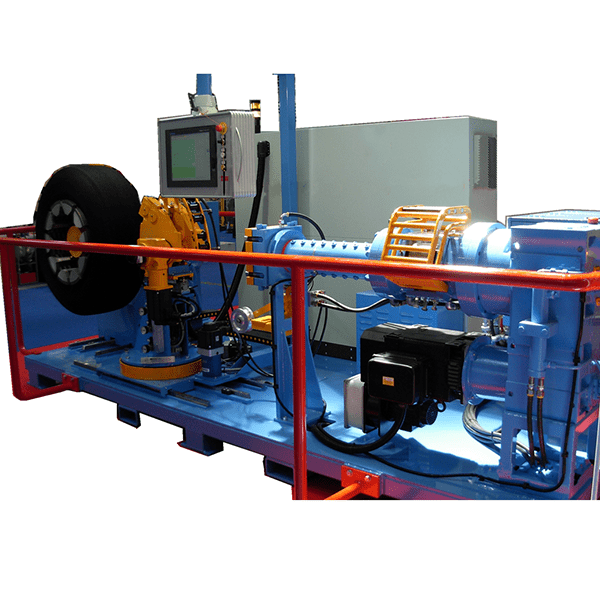

Ftc-1422 tsheb lub log tsheb winding tshuab muaj tsib ntu, raws li qhia hauv daim duab

1 winding taub hau 2 winding puag 3 lub cav loj 4 puag 5 cov khoom siv cia khoom

1.1 winding lub taub hau

1) muaj nuj nqi: cov roj hmab sawb txuas ntxiv los ntawm kev rho tawm yog dov rau hauv cov duab uas yuav tsum tau ua los ntawm cov txheej txheem kom ntseeg tau tias cov khoom sib txawv thiab tsis sib thooj ntawm cov roj hmab sawb lub cev. Nyob rau tib lub sijhawm, cov hlua roj hmab txuas rau sab hauv lub log tsheb yog nias kom ntseeg tau nws cov ntawv cog lus nrog lub log lub cev thiab tshem tawm cov npuas ntawm qhov sib koom ua ke, uas yog qhov tseem ceeb heev rau qhov zoo ntawm kev sib tw.

2) cov qauv: taw qhia ntaus ntawv, dov ntaus, menyuam, sab roller, phau ntawv qhia kev tsheb nqaj hlau, thiab lwm yam

1 qhia ntaus ntawv 2 calender ntaus ntawv 3 cov menyuam sab 4 daim 5 coj qhia kev tsheb nqaj hlau

1.2 winding puag

1) ua haujlwm: ua kom lub taub hau winding txav rov qab thiab txav mus los, sib koom tes nrog lub tshuab loj kom ua tread kev luam txav, thiab tuaj yeem tig mus ua kom lub taub hau winding txiav tawm mus rau qhov chaw sib khi.

2) mechanism muaj pes tsawg leeg: puag winding, ntaus tig, pub ntaus khoom, thiab lwm yam

1 winding puag 2 tig yam khoom 3 pub cov khoom siv

1.3 tus tswv tsev

1) ua haujlwm: ua kom lub log tsheb txav ntawm ib sab mus rau sab, koom tes nrog cov neeg ua haujlwm winding kom ua tread luam kev txav, thiab tshuab lub log tsheb.

2) mechanism muaj pes tsawg leeg: tsav tsheb ntaus, nruas nruas, kem, txhais lus ntaus, thiab lwm yam

1 tsav tsheb ntaus ntawv 2 nthuav nruas 3 kem 4 txhais lus ntaus ntawv

Parameters Cov lus qhia txwv tsis pub

2.1 kev ua yeeb yam tseem ceeb

· Hom log tsheb: cov log tsheb tsheb

R cov npoo nyiaj siv: 16 "~ 24.5"

Diameter cov log tsheb yam tsawg kawg nkaus: 700 hli

· Lub log loj tshaj plaws: 1,400mm

Tire yam tsawg kawg nkaus cov log tsheb nto: 150mm

· Qhov siab tshaj plaws log nto dav: 500mm

Muaj peev xwm ntau lawm: 90 hli Ø extruder (qhwv ntawm ib ncig 11.00 R20 log tsheb li 4 feeb, tread compound zoo 13 kg)

2.2 cov kev txwv tseem ceeb

· Log tig lub cev muaj zog: 1.5kw

· Xy mobile lub cev muaj zog: 0.55kw

Power qoj lub cev muaj zog: 1.5kw

· Dov lub cev muaj zog: 1.1kw

· Qhov kub thiab txias: 5 ~ 40 ℃

· Cov cua:

Huab cua tsis zoo: qhuav thiab huv

Cov cua ntsig txog: ≥ 0.8mpag)

2.3 qhov loj thiab qhov hnyav

Tshuab chav tsev thaj: 6000 × 3000 hli

Lub ntsiab qhov siab: 2000 hli

Lub tshuab hnyav: 2000kg

Results Qaij winding qhia pom

◐ Cov khoom siv Cheebtsam

1.X / Y / Z axis yog tsav los ntawm servo lub cev muaj zog, raws li cov qauv txheej nkhaus, kua nplaum winding.

2.Cov khoom ua haujlwm: Cov kav dej thiab cov ntsia hlau yog tsim los ntawm 38crMoALA, kev kho saum npoo hauv nitrogen.Hardness ntawm nitriding rau sab hauv sab hauv lub thoob: HV950 ~ 1000, qhov tob: ≥ 0.5mm.Screw nto nitriding hardness: HV900 ~ 950, qhov tob: ≥ 0.55mm.Qhov lub tog raj kheej adopts vuam qauv, thiab cov dej txias hauv lub tog raj kheej adopts drilling ncig channel los pab txhawb kev hloov kub ntawm qhov kub tswj dej thiab lub tog raj kheej.Qhov lub thawv yog nruab nrog tus pin mounting qhov, qhov ntau yog 8X6, sab hauv cov kav dej tuaj yeem tiv taus 1Mpa, 1 teev ntawm kev kuaj hydraulic, tsis muaj dej txeej.Qhov ntsia hlau thiab lub ntsiab ntawm lub tshuab hluav taws xob tau txuas los ntawm spline, thiab lub hau ntswj tuaj yeem raug rho tawm los ntawm sab xub ntiag extruder.Rau kev taw qhia ntawm ntsia hlau: txoj cai tig.Qhov ntsia hlau sab hauv tuaj yeem tiv taus 1MPa, 1 teev ntawm kev ntsuas hydraulic, tsis muaj dej xau.Hauv ntsia hlau sib piv: 14: 1.

3. chav tswj kev tiv thaiv kub ntau: plaub-channel kub tswj kev tswj hwm tau nruab rau ntawm ib sab ntawm lub tshuab txuas, siv kaw lub voj voos kaw, hloov pauv hloov cua txias dej, hluav taws xob cua, 4-channel, qhov kub thiab txias ntawm 45-100 ± 1 ℃.

◐ Cov Qauv Sib Tw

| Ntug loj me | 16 ”-24.5” |

| Log log txoj kab uas hla | 900-1250 hli |

| Log log dav | 400mm |

| Ntsia thawv hom | 120x14D |

| Precision ntawm winding tuab | ≤ mm 1mm |

| Precision ntawm winding dav | ≤ mm 3mm |

| Precision ntawm winding ceeb thawj | ≤% 1% |

| Qhov siab tshaj plaws viav Caw Lub ntsej muag mob | 150 ° |

| Symmetry taw tes tuab sib txawv | 1mm |

| Cim taw hnyav sib txawv | 1% |

| Lub Zog | 165Kw |

| Qhov ntev | 6000x2200x1850mm |

| Nyhav | 8000kg |

Kev sim ua ntawm lub tshuab winding

| Kev ceev ceev ntxiv ntawm cov specifications | Sai sai teeb tsa ciam ntawm qhov tsis |

| Ceev ceev sim xam ntawm tsuj taw winding nkhaus | |

| Lub voos winding yog xam los ntawm kev sim, thiab qhov tseeb laij yog ± 1.5kg | |

| Khi 2 log tsheb kom tau raws li cov txheej txheem xav tau | |

| Yuav muaj qhov zoo raunpaj cov roj hmab strips | Yuav siv qhov tsim nyog ntawm cov kab xev kom nws ua kom haum nrawm dua tread profile nkhaus |

| Ntxiv txoj haujlwm ntawm kev teeb tsa qhov chaw ntawm lub ces kaum, thiab ua kom cov lus tsa suab ntawm lub tshuab winding haum rau qhov nkhaus saum npoo ntawm lub log lub cev thaum 3D winding tau ua | |

| Faib kem teeb tsa muaj nuj nqi | Saj zawg zog txheej |

| Nrog fawm kib fai nqis, nws tuaj yeem hloov mus rau cov tread profiles yooj yim | |

| Winding pib txoj haujlwm xaiv kev ua haujlwm | Hloov chaw ntawm winding pib txoj haujlwm |

Inding Winding tshuab simulation system interface